Medical & Pharmaceutical Plastic Injection Molding

PF Mold has expertise in providing cost-saving, high quality injection molding solutions to the Medical Device industry. Our expertise in medical injection molding allows us to support tight tolerance micro-sized components to complete medical devices.

Our experts provide Project Management solutions from Concept to Operational Excellence, including full program documentation and component traceability.

| Technical Parameters | |

| Name: | Benefits of Medical Device Injection Molding with PF Mold |

| Clean Room | Class 10k and 100k Clean Rooms |

| Certification | ISO 13485:2016 Certified & FDA Registered |

| Team | Scientific Injection Molding Experts |

| Validation | IQ/OQ/PQ Validation, Per Customer Requirements |

| Service | Independent R&D, part development. |

| Material | resin ABS, silicone, PA6 and PC. |

| Package: | Sterilization and non-sterilization general packaging per clients idea or request. |

| Certification | ISO 13485 |

| Major markets | The United States, European Countries |

To provide our customers a single source solution, we offer ISO Class 7 (10K) cleanroom assembly and packaging services to complete your medical device injection molded project while adhering to the critical medical quality standards required when plastic injection molding medical parts. We offer complete quality control and inspection including IQ, OQ, and PQ validations, and lot traceability.

Using automated work cells to provide increased throughput and speed-to-market.

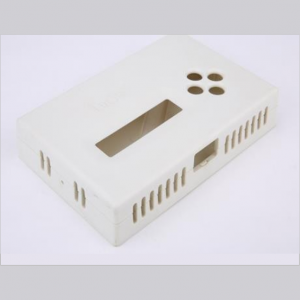

● Medical Enclosures

● Medical Knobs

● Needles

● Surgical instruments and blades

● Tubes

● Dental instruments

● Medical equipment components

● Prosthetics

We know you require quality and precision from your medical injection molding partner. At PF Mold, we draw on our extensive experience to take on your project at any step of development and can assist with engineering, manufacturing, post-molding operations, and up-scaling of production when necessary.