factory Outlets for Vertical Cnc - Precision CNC Machining Services – China Metal Fabrication – PF Mold

factory Outlets for Vertical Cnc - Precision CNC Machining Services – China Metal Fabrication – PF Mold Detail:

CNC machining parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. PF is an accomplished CNC supplier that engaged in a broad range of CNC machining applications.

Efficient CNC machining factory for mass production rapid prototyping service

Average 7 days turnaround time and 99.85% on time delivery

Multiple options of machining materials to meet specific properties.

Fast free quotation within 24 hours after inquiry

High customer satisfaction and loyalty

Rich design and manufacturing experience

| Technical Parameters | |

| Size: | Custom |

| Material: | 1.2311 |

| Hardness: | Untempered |

| Function: | CNC Machined Parts |

| Documentation: | Inspection report, Material certificate |

| Process tolerance: | +/-0.005mm |

| Manufacturing Lead time: | 27 days |

| Transportation lead time: | 5-7 days |

| HS code: | 84879000 |

| Quality Management System: | ISO9001, 6S Principle |

1. Show your customers and investors a model of your product.

1. Demonstrate the appearance, dimensions and features of your product.

2. Test your design for its suitability.

3. Save time and money by identifying and reducing design flaws.

4. Improve and streamline the production process.

5. Reduce your work load when the time comes to manufacture.

6. Create multiple versions with different colors, surface textures and finishing processes.

CNC machining provides less variance and greater efficiency compared to other metal fabrication methods that involve more manual input. Computer-aided machines operate faster than human-operated machines while producing fewer errors, reducing material waste, and saving time.

Finishes For CNC Machining

Premium can produce parts by CNC Machining with tight tolerance+/-0.02mm and fine detail from a variety of metal or plastic materials.

Due to the subtractive nature of CNC, minor tool marks will be visible on the surface of the part after machining. A number of post-processing and finishing methods can be applied to improve the surface roughness, visual properties and wear resistance of the CNC machined parts.

Now we discuss the most common metal CNC finishes to help you select the most suitable surface finish for your application.

● As machined

● Sandblasting with Anodizing

● Hard anodizing

● Powder coating

● Nitriding

● Heat treatment

● E-coating

● Painting

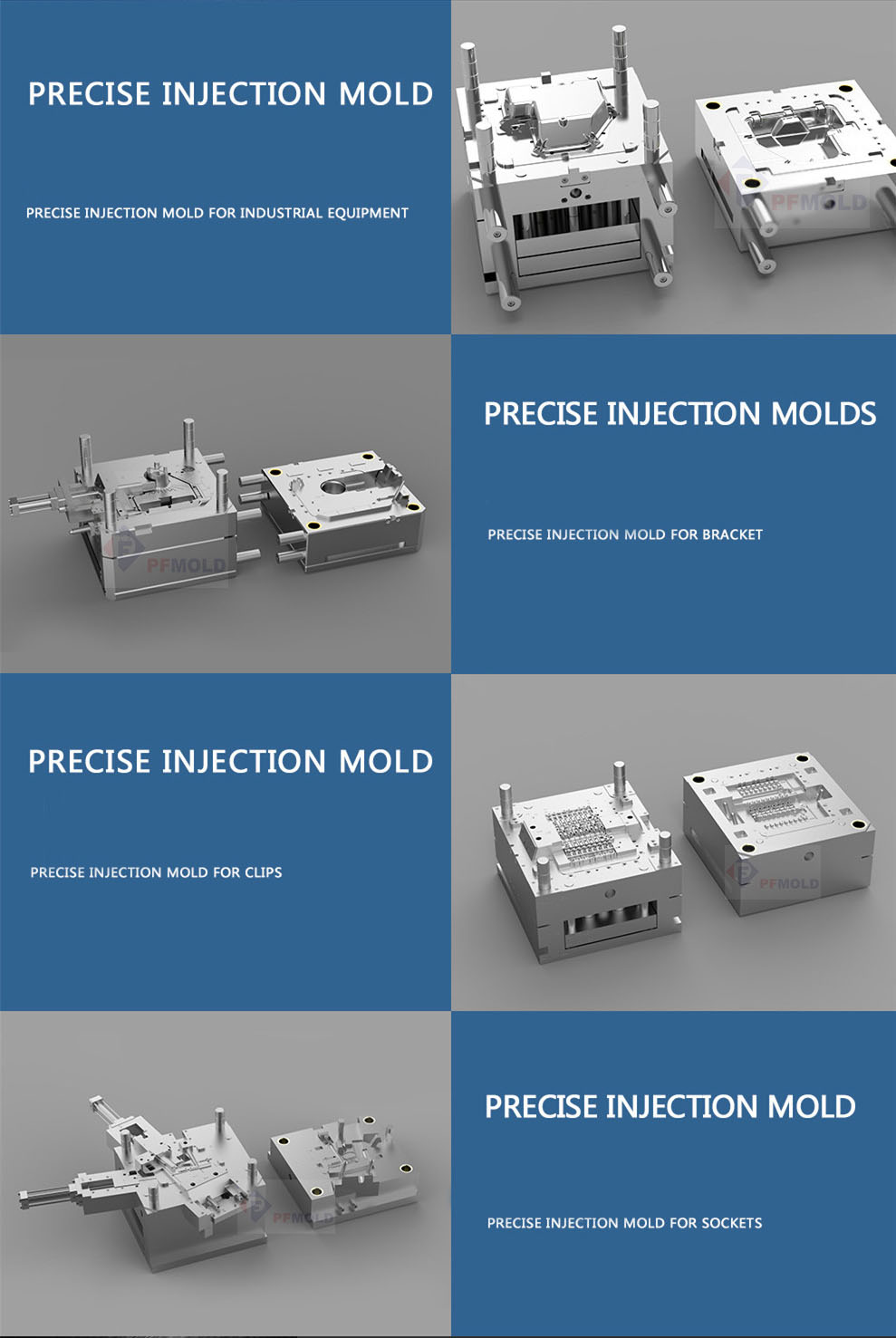

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for factory Outlets for Vertical Cnc - Precision CNC Machining Services – China Metal Fabrication – PF Mold , The product will supply to all over the world, such as: azerbaijan, Johor, Switzerland, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!