Quality Inspection for Rubber Injection Molding - Bluetooth speaker cover grey abs Bluetooth speaker mold speaker plastic cover molding – PF Mold

Quality Inspection for Rubber Injection Molding - Bluetooth speaker cover grey abs Bluetooth speaker mold speaker plastic cover molding – PF Mold Detail:

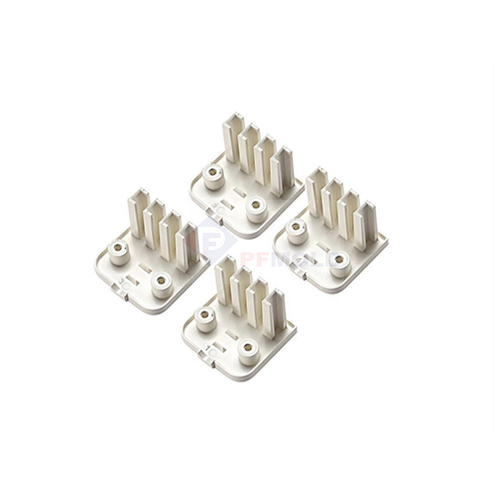

Model No.: P1805G14

Shaping Mode: Injection Mould

Surface Finish Process: Mirror Polishing

Mould Cavity: Multi Cavity

Plastic Material: ABS

Process Combination Type: Single-Process Mode

Application: Car, Household Appliances, Commodity, Electronic, Home Use

Runner: Hot Runner

Design Software: Pro-E

Installation: Fixed

Certification: CE, ISO, SGS, FDA

Standard: DME

Customized: Customized

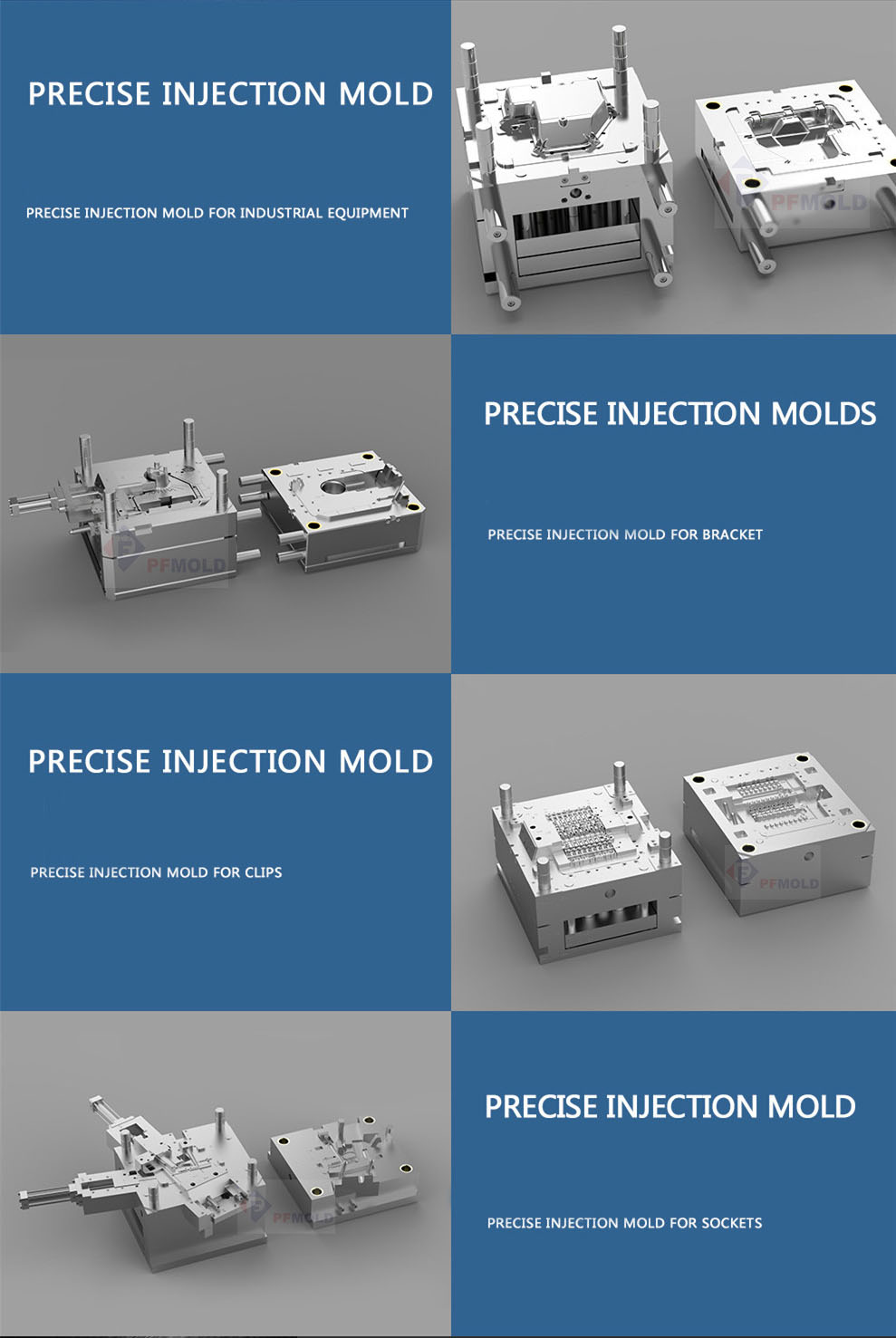

With many manufacturers offering injection molded plastics, PF MOLD believes our true success comes only from an approach and commitment to Plastic Injection Molding that provides each customer unparalleled competitive advantage in terms of improved quality, appeal, efficiencies and increased profitability. Transparent Plastic Molding, Over Molding ,Plastic Molding,Metal Injection Molding.Family Injection Mold ,Injection Mould Electronic Products,Automotive Family Mould, Daily Use Moulding.

1. We have been doing professional plastic part and plastic parting products for 12 years, equipped with 30 sets mold processing equipment, proffessional CAD, CAM, CAE technology and special testing equipment.

2. Rich experience for export standard mold.

3. Our die include: Auto Parts , household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc…

4. We can quote the RFQ within 8-24 hours.

5. Skilled Mold Design to avoid any modification.

6. Help to improve the part design to save the mold cost.

7. Strictly mold tooling process control to delievry on time.

8. Professional sales to avoid the communication mistake.

| We promise | All customer-centric, never for short-term profit, and sell long-term benefits |

| We produce | Mold, prototype, injection molding, die casting, product assembly, surface printing, spraying the surface integration |

| Pls provide | 2D, 3D, samples, or the size of the multi-angle pictures |

| Mould Time | 20-35 Days |

| Product time | 7-15 Days |

| Moud precision | +/-0.01mm |

| Mould life | 50-100 million shots |

| Producing Process | Audit drawings - mold flow analysis - design validation -Custom Materials – mold processing - core processing - electrode machining - Runner system processing -parts processing and procurement - machining acceptance - cavity surface treatment process -complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

| Mould cavity | One cavity, multi-cavity or same different products be made together |

| Mould material | P20, 2738, 2344, 718, S136,8407, NAK80,SKD61,H13 |

| Runner system | Hot runner and cold runner |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Standard | HASCO, DME or dependent upon |

| Main thechnology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Software | CAD, PRO-E, UG Design Time: 1-3 days (normal circumstances) |

| Product material | ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC, HIPS, PMMA, TPE, PC/ABS, TPV, TPO, TPR, EVA, HDPE, LDPE, CPVC, PVDF, PPSU PPS. |

| Quality system | ISO9001:2008 |

| Establish time | 20days |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, etc plastic part |

Looking for ideal Bluetooth Speaker Cover Manufacturer & supplier?

We have a wide selection at great prices to help you get creative. All the Bluetooth Speaker Mold are quality guaranteed. We are China Origin Factory of Speaker Plastic Cover Molding. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Quality Inspection for Rubber Injection Molding - Bluetooth speaker cover grey abs Bluetooth speaker mold speaker plastic cover molding – PF Mold , The product will supply to all over the world, such as: Greece, The Swiss, Uruguay, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!