Short Lead Time for 3d Chicken - Bi-color mold, OEM plastic two color molded parts – PF Mold

Short Lead Time for 3d Chicken - Bi-color mold, OEM plastic two color molded parts – PF Mold Detail:

Two-shot injection molding uses a single process to create parts that have multiple pieces. This allows manufacturers to create more complex pieces without the risk of contamination, which is a common problem when combining pieces molded through two different processes. Parts created through two-shot injection molding are far more durable than parts composed of individual pieces that are molded separately; they are shock-resistant, form stronger seals, and create color patterns that won’t wear off. As an added bonus, the single process of two-shot injection molding is less expensive and more efficient than creating parts using two or more distinct processes, so you’ll save time and money while producing a higher-quality product.

| Technical Parameters | |

| Name | Multi-color molding parts |

| Color: | Customized |

| Materials: | Products requiring different materials, such as rubber and plastic components |

| Function: | Moving parts molded in a single cycle |

| Injection molding process | clamping–filling–(gas-assisted, water-assisted) pressure—-maintenance—cooling—opening—- demoulding |

| Core materials | P20, 718, NAK80, S136, SKD11, 1.2738, 1.2311, 718, or customized |

| Manufacturing Lead time: | 60 days |

| Transportation lead time: | 5-7 days |

| Product origin | China |

| Supply capacity | 500 molds per year |

Two-shot injection molding is a technique for layering two or more materials in different shapes on top of one another to create the finished product. It requires specialized machines that can complete the injection molding process twice in a single cycle. In the first step of this process, one material is injected into the mold to form the main shape. This shape contains holes or spaces, which are then filled in by the second material when it is injected in step 2.

Two-shot plastic injection molding, co-injection, two-color, and multi-component molding are all variations of an advanced molding technology

Combining hard plastics with soft materials

Two-step process performed during a single press machine cycle

Consolidates two or more components thus eliminating additional assembly costs

Designers and customers constantly try new uses for plastic injection molding parts produced using multi-step molding processes.

These applications usually occur in the following types of

l high-end desktop computers

l Multi-color molding parts

l Child supplies with moving parts

l lighting buttons for car navigation units

l Parts with sealing requirements

l All kinds of air conditioning

l Soft material handle

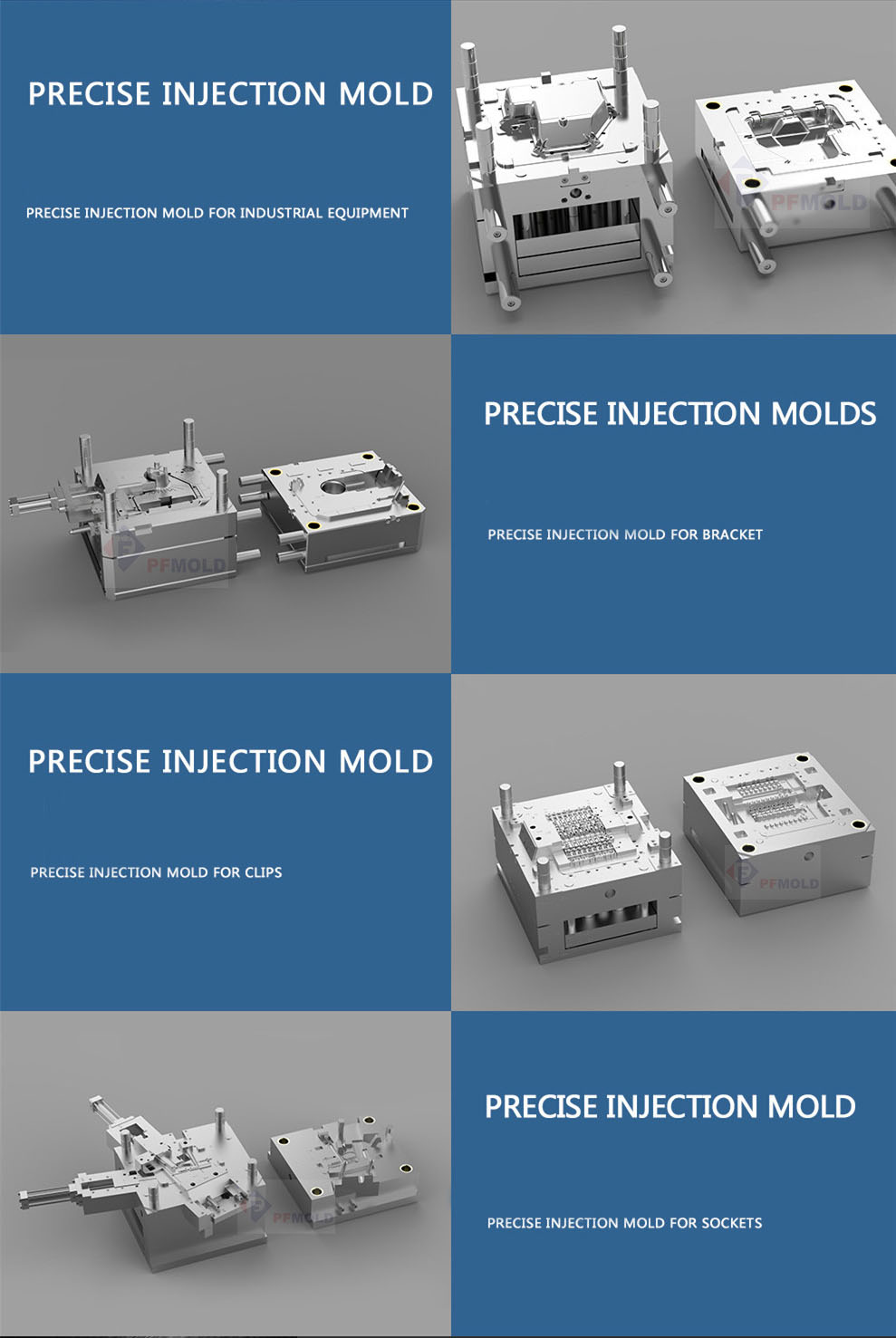

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Short Lead Time for 3d Chicken - Bi-color mold, OEM plastic two color molded parts – PF Mold , The product will supply to all over the world, such as: Brunei, Georgia, Canada, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!